A biodigester is a device that is able to convert manure and water into methane gas efficiently, cleanly, and cheaply. In order to effectively use a biodigester, manure and water is collected and mixed together. Allowing this solution to ferment, methane gas is produced, and it is then extracted from the biodigester and used for cooking. As fresh manure and water is added to the biodigester the used, fermented mixture is naturally released into an overflow tank and can then be used for fertilizer. This post will explore smaller biodigesters in developing nations which are used for individual homes and farms.

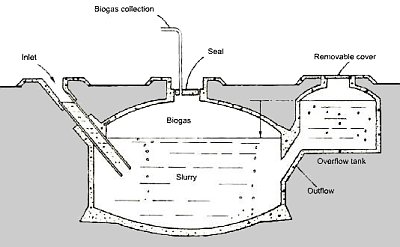

There are many different variations of biodigesters, depending on location, size, affordability, and demand of methane. However, all biodigesters have three main elements. The first piece is an inlet valve. This is where the manure is mixed with water, and fed into the main chamber. The manure to water ratio is about 1 Kg of manure to 15 L of water. Rainwater may be used in a biodigester as its main purpose is to simply liquify and quicken the fermentation process. After the mixture of manure and water, now known as slurry, has been created it then travels into the main chamber. The main chamber is usually around 1 cubic meter in size and it is where the fermentation process occurs. As slurry builds up in the main chamber, methane begins to separate out of the slurry. The methane collects at the top of the chamber, and is forced through a thin gas line which can power the stove of a household. As more slurry is added into the main chamber the methane depleted slurry is then pushed into an overflow tank where it may drain or be collected.

The cost of a household biodigester can vary depending on material. In more developed countries materials such as concrete, cement, and plastic layering can increase the efficiency, but it also increases the price. The most affordable unit is made from plastic, and costs roughly $40.00 american, as well as two days of labour to install. However, this investment can pay for its self in as little as four months. The general rule for the amount of manure needed states that four to five pigs can create enough manure to supply a biodigester for a family of four to five people.

This product allows wet waste (rain water) to be mixed with the waste of cattle and livestock to create a cheap way to cook food. The fermented slurry feeds nck to the system as it is a perfect fertilizer for crops. There is also no energy expended on transportation as all of the processes take place on individual farms. Biodigesters use less resources, not to mention significantly less man power, to create fuel for cooking and greatly decreases the amount of methane pollution.

Problems arise with biodigesters as they may be considered too expensive for some families. If the biodigester is not used regularly, solids can form inside the main chamber, which can result in significant decreases in efficiency. Improper installation can result in problems with the flow of the slurry and the amount of leakage in the system.

Overall the biodigester presents an interesting opportunity for both developing and developed nations to utilize waste to create a cheap green source of fuel.

This is a video demonstrating the use of a biodigester in a more developed country:

- Aidan Mitchelmore

Notes

Bui Xuan An, L. Rodriguez J. et. al., “Installation and Performance of Low-Cost Polyethylene Tube Biodigesters on Small-Scale Farms,” January 1997, http://www.fao.org/ag/aga/agap/frg/feedback/war/W5256t/W5256t06.htm (accessed November 4, 2009).

Big Gav, “Banana Methane Powerered Cars Pig Poo Power And Other Uses For Biogas,” September 1, 2009. http://www.theoildrum.com/pdf/theoildrum_3633.pdf (accessed November 4 2009).

Smart Innovations Canada, “Biogas Digestion,” Smart Innovations, http://www.smartinnova.com/index.php (accessed November 3, 2009).

Renewable Energy and Environmental Information Network, “Biogas Uses For Cooking Purposes At Noakhali,” Biomass Program in Bangladesh, September 3, 2009, http://www.reein.org/biomass/biogas/noakhali/(accessed November 4, 2009).

No comments:

Post a Comment